Work centres

A Work centre represents a piece of equipment, machinery or any type of resource that is used to manufacture goods. Examples of Work centres include a drill, lathe, moulding machine, oven or assembly bench.

The manufacturing process for every item that you make can be broken down into distinct steps, each of which requires a piece of equipment or manufacturing resource to complete. For example, to manufacture a gardening tool, the following steps may be required:

- Cut steel

- Weld parts together

- Galvanise

- Paint

- Package finished tool

By defining a list of the available Work centres in your business, you are able to break up your Work orders up into steps or routes - each of which uses a specific Work centre. Once a Work order has been defined in terms of the Work centres required to complete the Work order, Accentis Enterprise can then provide information on Work centre usage, availability and scheduling.

Work centres can also be used to represent external contractors that may be involved in the manufacturing process, such as a paint shop or galvanising service. Such Work centres can then be used in routings for a manufactured item just as if they were done in-house.

- No practical limit on the number of Work centres that can be created

- Work centre codes are FlexiCode, allowing the Work centre code to be changed while still retaining all internal links to that Work centre

- Each Work centre can have its own Schedule and costing values associated with its use

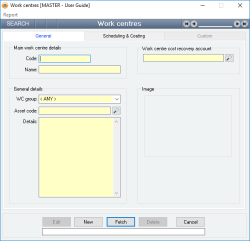

Module: Manufacturing

Category: Work centres

Activation: Main > Manufacturing > Setup > Work centres

Form style: Single instance, SODA

Special actions available for users with Administrator permissions:

- Change the User ID of the Entered by field of memos.

- Edit memos entered by other users.

Database rules:

- A Work centre cannot be removed if it is referenced in an item route or a Work order route

- Work centres must have unique codes

Reference: Select from list, Mandatory, HotEdit, WYSIWYS

This is the group to which this Work centre belongs. The Work centre group is used to provide a simple classification of the Work centre.

Reference: text(15), AutoComplete, QuickList, WYSIWYS

This is the code of the fixed asset that represents this Work centre, if one exists. In idle mode, clicking on the asset code will take you directly to the asset record. If an image has been assigned to the asset code, this image will be used as the default image for the Work centre and will become visible in the Work centre once the record has been updated.

Reference: memo, expandable, WYSIWYS

These are any general details and can contain any relevant information relating to the Work centre.

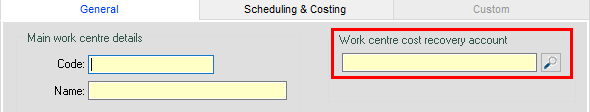

Reference: account, QuickList, WYSIWYS

This field allows a General Ledger “Cost recovery” account to be assigned for the Work Centre

Whenever a timesheet is entered for a Work Order, and the timesheet also references a route that relates to this Work Centre, then a Cost recovery transaction is performed on update of the timesheet as follows:

- The Work Centre cost recovery account is CREDITED

- The Work Order’s WIP account is DEBITED

- The Amount is the number of hours recorded on the timesheet multiplied by the Work Centre Cost / hour on the “Scheduling and Costing” tab.

Last edit 10/02/23

Reference: Image

This displays a graphical image representing the record, which can then be used on the screen as a visual aid, or in reports which can then be printed, faxed or emailed to customers.

To add an image to a record

Right-click with your mouse in the image box, click on Select image from the popup menu and then select the image file required. Both JPG and BMP file types are supported.

If an image is not selected

If there is a .jpg or .bmp document attached to the record with the word photo in the file name, it will automatically be displayed as the image for that record.

If a record is part of a Product group, the image assigned to that product group will display by default.

Image sizing

Once an image has been added to a record, it is displayed fitted to the size of the image area. If the ratio of the image is not the same as the ratio of the image area, the image will be stretched to fit the image area.

If the full image is not required on the form, you can select the required section of the image by double clicking on it. This will display a full sized version of the image upon which you can highlight, via clicking and dragging the mouse, the area you wish to see by default on the form. The selection area will automatically snap to the same ratio as the display area on the form, so that when the selection is displayed, it will not be distorted due to stretching.

To reposition the highlighted area in the horizontal plane during selection, hold the control key down while moving the mouse.

The size of the image selected will impact on the speed at which you can cycle through records displayed on the form, particularly if the images are accessed over a network or the internet. It is recommended that only JPEG (compressed) images are used.

Last edit 06/09/23

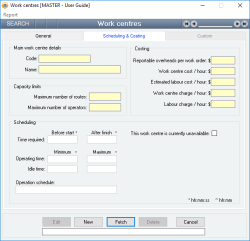

This is the maximum number of people that can be working at this Work Centre at the one time. It is used to determine how many person-hours are available at this Work Centre for scheduling purposes.

This data is used on Capacity usage reports such as SA4005 and SA4253. This data is often also integrated into user-defined and customised reports.

Last edit 10/02/23

This is the cost added to every Work Order that uses this Work Centre, regardless of how much it uses it.

These are just used on reports of your choice. They are a “user defined” field and as such do not appear in any standard reports. That means you can use them and integrate them into reports as you like.

Last edit 10/02/23

This is the cost for using the Work Centre per hour. For any reports that show the estimated Work Centre cost for building a Kit, this is the Cost that is used, and is multiplied by the number of hours under consideration. For example, for a Kit Item that has not been built, each route has an estimated number of Work Centre hours. These hours are multiplied by the Cost to arrive at an estimated Work Centre Cost to build that Work Order.

When timesheets are entered, this Cost is also used for cost recovery when the Work centre cost recovery account is filled in:

Then, for every hour recorded in the timesheet, this cost is CR from the recovery account and DR into the work order WIP account, and ends up in the stock on hand.

Last edit 10/02/23

This is an estimated cost for labour to run the Work Centre every hour. This is only an estimate and is not used in any transactions.

It is used in reports that estimate production costs, such as:

- Manufacturing > Reports > Production analysis > Production analysis (finished workorders by workorder) (SA1240),

- Inventory > Reports > Kits | Bill of materials costing analysis (drilled) (SA3836)

- Inventory > Reports > Kits | Routing list (grouped and detail, drilled) (SA4595)

Last edit 10/02/23

This is the charge per hour that you would use if you were going to create a billing report based on the time that this Work Centre was utilised for a Job or Work Order

This figure is not used in any standard Accentis reports. It is for user customised reports only.

Last edit 10/02/23

This is the charge per hour that you would use if you were going to create a billing report based on the time that a person spent at this Work Centre for a Job or Work Order

This figure is not used in any standard Accentis reports. It is for user customised reports only.

Last edit 10/02/23

Reference: time

This is the time that is required BEFORE the Work centre is ready to be used. This time should include any preparation and start up times relevant to the Work centre. For example, an oven may need to heat up before it can be used.

Reference: time

This is the time that is required AFTER the Work centre has been used. This time should include any clean up and shutdown times relevant to the Work centre. For example, a paint brush may need to be washed after use.

Reference: time

This is the MINIMUM amount of time that the Work centre must be used for AT ONE TIME. For example, once turned on, an oven may be required to remain on for at least an hour before it can be safely turned off.

Reference: time

This is the MAXIMUM amount of time that the Work centre can used for AT ONE TIME. For example, a cordless drill may have a battery life of 1 hour when being used before it needs recharging.

Reference: time

This is the MINIMUM amount of time that the Work centre must be idle for between uses. For example, a cordless drill may require a minimum of 2 hours recharge time after being used.

Reference: time

This is the MAXIMUM amount of time that the Work centre can be idle for between uses. For example, an engine may be required to be started every week to ensure it does not cease.

Reference: text(255), expandable

Information is under review for a new version and will be updated soon.

Reference: Yes/no

This field allows users to designate a Work centre as being unavailable for use. This may be because the Work centre no longer exists, is under maintenance, or is faulty and not operational in some way. This field could also be used within a pool of Work centres where you may only want a certain number of them to be available at any one time.

This does not produce any errors or reports, and is solely informational. You will still be able to use the Work centre unless you have also set its Capacity limits to 0.

Last edit 27/09/23

Reference: Memo

Information is under review for a new version and will be updated soon.

Reference: Date

Information is under review for a new version and will be updated soon.

Reference: Time

Information is under review for a new version and will be updated soon.